Float Switches

Albany LEVCON series level switches are typically used for providing signals for pump or valve operation and high and low alarm signals. A typical application may be a tank filling process requiring a low alarm, pump on, pump off and high alarm liquid level sensing.

Albany LEVCON series level switches are typically used for providing signals for pump or valve operation and high and low alarm signals. A typical application may be a tank filling process requiring a low alarm, pump on, pump off and high alarm liquid level sensing.

Albany LEVCON’s are manufactured using best practice manufacturing techniques and quality components insuring a high quality reliable sensor.

All Floats are 316 Stainless Steel. All housings are Nema 4X, Explosion Proof,Class I, Div 1, Group C & D, with 20 Watt, SPST Switch(250 V & 500mA max) and 24″ Wire, 22Ga PTFE.

Many options are available with our Multi Level Float Switch design including a short float that enables independent float switch positions to be only 1” apart. This is especially beneficial for applications where precision control signals are needed in a shallow tank.

- Loop or Day Tank Fuel Oil Transfer System

- Microprocessor Based Monitoring and Control with Automatic Lead/Lag Function

- Tank Monitoring

- Building Automation System (BAS) Interface

- Alarm and Event Summaries

Albany SICON and DUCON Microprocessor Based Fuel Oil Management and Pump Controller are cUL and CSA Listed, with NEMA Rated Enclosure. They are configured to monitor and control transfer pumps, return pumps, tank level gauges, and tank leak detectors.

Albany SICON and DUCON Microprocessor Based Fuel Oil Management and Pump Controller are cUL and CSA Listed, with NEMA Rated Enclosure. They are configured to monitor and control transfer pumps, return pumps, tank level gauges, and tank leak detectors.

It provides pump operation and monitoring with:

- Disconnect Switches;

- Magnetic Motor Starters,

- Hand-Off-Auto Selector Switches,

- Pilot Lights for ‘Power On’, Motor ‘Run’ and Motor ‘Trip’,

- Terminal Strip,

- Pump Failure Pilot Light and Manual Reset,

- Audible Alarm Buzzer and Silence Push Button,

- High and Low Pressure Cut Outs/ Red Pilot Light/ Reset,

- Provisions for Main Tanks (1) and Day Tanks (1) Status (High Level, Critical High Level, Low Level, and Leak Detection) with Red Pilot Lights and Dry Alarm Contacts for each,

- Pump Set Basin Leak Detection Signal and Red Pilot Light.

Our approach is to build standard systems with features that can be enabled on site as well as a set of options that can be added to each system. The Controller can network with other system controllers using Ethernet, and directly to Building Management Systems with an option of BACnet, Modbus, Metasys N2, or Lon protocol.

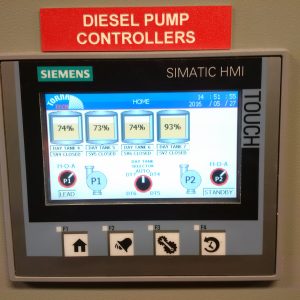

Our HDA Model Controls system features HMI ( Human Machine Interface ) c/w Color & Touch screen (factory programmed) & PLC ( Programmable Logic Controller) c/w Analog and Digital Inputs and Outputs (factory programmed).

Our HDA Model Controls system features HMI ( Human Machine Interface ) c/w Color & Touch screen (factory programmed) & PLC ( Programmable Logic Controller) c/w Analog and Digital Inputs and Outputs (factory programmed).

The design intent of the HDA System is to give the Operators and Design Engineers flexibility in the design and deployment of their systems. Our controls provide the security of fail-safe operation with a focus on communications.

Features of the system include:

- Graphical Display,

- Graphical User Interface,

- Pump Motor Run,

- Pump run elapsed time,

- Pump number of starts counter,

- Lead pump failure indication & virtual manual reset,

- Lag pump start,

- P1 – Auto – P2 alternating virtual selector switch,

- Continuous main tank level monitoring and display in % of full tank,

- Continuous day tank level monitoring and display in % of full tank,

- Continuous system pressure monitoring and display in PSI,

- Overload alarm indication,

- Low level day tank alarm indication,

- High level day tank alarm indication,

- Critical high level day tank alarm indication,

- Low level main tank alarm indication,

- Shutdown or alarm are field selectable,

- High level main tank alarm indication,

- Critical Low level main tank alarm indication,

- Low system pressure alarm indication with virtual manual reset,

- High system pressure alarm indication with virtual manual reset,

- Tank Vacuum leak alarm indication,

- Pump set basin leak alarm indication,

- Valve Open / Close Status

Sometimes you have a project so unique that a standard system won’t provide the level of control necessary. You can work directly with our application experts to design a system that satisfies current codes and regulations while meeting operational requirements. Though this system may be complex our Controls Engineers can ensure that the operation is effortless and the integration is easy.

Albany Controllers can network with other system controllers using Ethernet, and directly to Building Management Systems with an option of BACnet, Modbus, Metasys N2, or Lon protocol.